Get YouTube subscribers that watch and like your videos

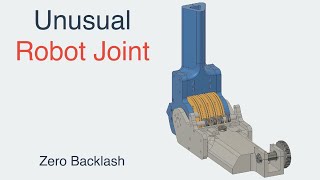

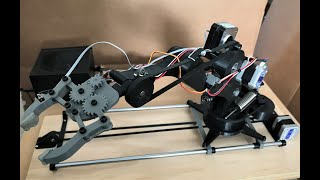

15:1 NEMA-17 Robot Actuator (3D Printed)

I designed this actuator in SolidWorks and 3D printed the plastic components. It uses a twostage timing belt reduction to provide the motor mechanical advantage. It has at least 3.6 Nm of dynamic torque running at approximately 1.8A.

As shown in the noload precision test, the actuator is capable of submillimeter precision with a 0.55m lever arm.

The first stage is a 5:1 reduction, and the second stage is 3:1. Each stage uses a 200mm loop of GT2 timing belt. Generating sufficient belt tension in the second stage was the largest challenge. I settled on using an adjustable idler bearing, which can be seen in some of the images.

Recommended