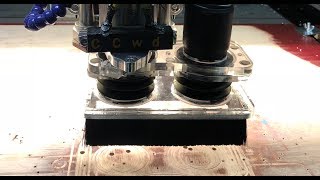

CNC Build Ep 10: Print Your Own CNC Dust Shoe for The Best CNC Dust Manifold Design

Hey CNC Woodworkers! I designed a CNC Dust Boot (Dust Shoe, or Dust Manifold) and I have the model files available for you to download for free, so you can print one at home on a regular (smallish) format 3D printer. This is my second version for a CNC dust shoe. In this video I discuss some of design goals and considerations, tips on how to print the dust shoe, how I assemble it, and finally some notes on how much the materials will cost.

July 2024 Update: Version 3 is now available: • CNC Dust Shoe Version 3! Print your o...

Download: https://www.corbinsworkshop.com/shop/...

This is a completely free digital download for a CNC Dust Shoe design that fits various typical spindle sizes. It is designed in Fusion 360 using parameters that can easily be customized. I also included STL files for various spindle sizes. You can print it on your typical home 3d printer, such as the Prusa i3 MK3s (etc). My design goals: thin and skinny to fit between an Automatic Tool Changer tool station without docking the boot, long enough to perform an ATC tool change, removable dust port to use it as a vacuum, and a removable brush hood, with an optional split design. I use it on a HITECO QD1F spindle, but I know some people have had good success using my v1 design on other spindle sizes. I have an Avid CNC, but this design should work fine on any brand CNC machine. I wanted to make it even easier for people to print, so I also included the presetup PrusaSlicer .3MF files which show all my print settings. You can download PrusaSlicer for free and open up the files to see how I set it up for printing.

If you don't want to print this yourself, then I'd recommend checking out the Etsy Store for OneGuyInAShop and buy one of his excellent designs: https://www.etsy.com/shop/OneGuyInAShop (no affiliation)

Note: I incorrectly calculated the total cost in the video because I counted the magnets wrong; it is more like $47 in materials, or cheaper if you use some cheaper quality PLA and different magnets.

CNC Build Playlist: • Avid CNC Build

Ep 1: What CNC To Buy • CNC Build Ep 1: What is the Best CNC ...

Ep 2: Welded CNC Table • CNC Build Ep 2: How to Weld a CNC Bas...

Ep 3: Making an Avid CNC Precise: • CNC Build Ep 3: How to Make an Avid C...

Ep 4: How to Tram a CNC: • CNC Build Ep 4: How to Tram a CNC C...

Ep 5: Automatic Tool Changer: • CNC Build Ep 5: How to Setup an Autom...

Ep 6: ATC Tool Rack Build • CNC Build Ep 6: Automatic Tool Change...

Ep 7: ATC Setup in Mach 4 • CNC Build Ep 7: Custom Mach 4 ATC Too...

Ep 8: ATC Tool Heights • CNC Build Ep 8: How to Set Tool Heigh...

Ep 9: ATC Post Processor Setup • CNC Build Ep 9: ATC Post Processor Mo...

Ep 10: 3D Printed Dust Boot • CNC Build Ep 10: Print Your Own CNC D...

Ep 11: Improving the Avid CNC Table • CNC Build Ep 11: Improving the Welded...

Ep 12: CNC Spoilboard • CNC Build Ep 12: Make the ULTIMATE CN...

Support my channel by subscribing!

thanks everyone,

Corbin Dunn

https://www.corbinsworkshop.com // Products / Files / Downloads

https://www.corbinstreehouse.com // Blog

Chapters:

0:00 Intro

0:32 Design Goals and Features

5:07 3D Printing Tips & Issues

8:11 Assembly and Notes

12:10 Conclusion and Material Costs

#cncwoodworking #cnc #avidcnc