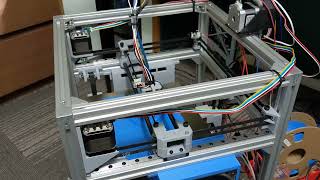

CoreXY 3D Printer Build All Metal Extreme

SolidCore Printer

See Updates https://3ddistributed.com/corexy3dp...

Join the Discord Channel / discord

Facebook Group / solidcore3dprinter

The newest printer build is coming along nicely. We decided to explore the CoreXY motion system. There’s still much work to be done along with some design decisions/changes to make.

SolidCore Printer

The whole idea is to build a printer that has:

Modular

Scalable

Linear Rails

Balanced Carriage Pull

Enclosure

BOM utilizes most available parts

All Metal Parts or 3D Printed

ZAxis: Independent Driven or Shared Belt Routing

There’s a lot of wasted space at the moment when you compare print area to the actual size of the build. The extra length and width gives me room to make more adjustments as the design process moves forward. It’s easier to cut extrusions and material then re buy or remake parts. At the moment the current build volume is about 350mm x 350mm x 350mm. After we make next set adjustments and assemble the next updates we’ll be looking at 400mm and a 500mm build plate.

We’ll probably make some changes such as reorienting the the yaxis linear rail into a vertical position similar to the RailCore, redesigning the carriages and motor/belt mounting plates where the zaxis motors are placed on the bottom of the machine. When I first designed the plates I thought it would look cool with the motors on top but after I machined everything I realized that moving the bed up and down could cause deflection in the main plates. I’m also considering making the carriage components and rail support one piece similar to the latest update on E3D’s Tool Changing printer.

We’re working on a small budget lol which “recycling” parts from previous builds. For example the bed is made from 3/8 inch thick aluminum that we robbed from an old printer. We’ll change that to 1/4 inch thick once we get more money.

The overall footprint of the machine relative to print volume is somewhat excessive. In order to have a solid enclosure design I had to move the motors inside the frame boundary. This sacrificed the overall printer size to print volume ratio.

We’re aiming to balance the pull to the center of carriage instead above it or below. It seems to be more rigid and minimize deflection. The belts are somewhat within the same plane of the three linear rails to avoid rocking cantilever loads that other designs may have with the belts up high or down low.

This design was inspired by the RailCore, HEVO, DBot, Mike Fisher’s QuadRod and Maarten van Lier’s corexy build.

CoreXY Kit

The all metal upgrade has a mechanical designer corner plates that position the zaxis motors at the top of frame along with the crossing belts. Once we work out the geometry we’ll offer the components 3030 extrusion.

CoreXY Design

The CoreXY 3d printer design is very different than most common 3d printer motion systems that have dedicated stepper motor for each axis. The corexy motion system is designed to minimize torque while moving the gantry and carriage.

CoreXY Advantages

The Advantages of the corexy system is the increased print speeds that can be achieved due to the light weight carriage. While 3d printing is a very slow process any kind of reduction in print time is much needed. In addition to faster print speeds the smooth motion that the core xy uses is also known to reduce artifacts commonly found in 3d printed objects.

CoreXY Kinematics

The corexy kinematics mechanical arrangement includes a unique motor movement where

X or Y motor move together or opposite of each other to move the carriage from left to right or towards or away . If you were to move just one motor you would see the print head move diagonal.. If the two motors move opposite of each other the print head will move along the Xaxis, If the two motors move in the same direction the carriage will move along the Yaxis.

CoreXY vs Cartesian

Most printers utilize Cartesian or plotter style motion where one or two motors will move the carriage from left to right or towards and away. This is the simplest approach in 3d printer motion. While the core xy setup is more complicated but a more efficient approach.

CoreXY Belt Path

The corexy 3d printer belt path has been explored in many mechanical arrangements. The main two corexy belt routing methods are belts crossed or not crossed. The main focus should be to keep the belt routing path parallel to the X and Y guide rails. There’s an excellent blog about corexy belt path by Mark Rehorst. The Hbot uses the same concept of carriage motion as the corexy but is much more simple and requires less math. In addition the hbot is harder to “get wrong.” The corexy’s disadvantage is that it requires two belts on two separate planes. The coreXY balances the forces while moving the gantry or carriage to minimize “racking’.