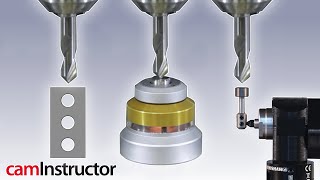

Cutter Compensation: when and how to use it

In this video, @GCodeTutor explains the basics of cutter compensation and how to program your CNC machine correctly using Gcodes G41 or G42.

Why do we need cutter compensation? If didn't use cutter compensation and we programmed our tool paths to be the same size as our part, we would end up with a part undersized by the radius of our cutter. This is because we program to the center line of our cutter, so if we are programming our dimensions on our part, the centerline or the tool would follow that path and not the cutting edge.

So that means we either have to program our part a little bit bigger to compensate to the radius of our cutter or we can use cutter compensation.

When we use cutter compensation, the machine automatically compensate to the radius of our tool so that we are cutting to the size of the part.

For cutter compensation to work, the machine needs to know the diameter of our tool. So if we are using a 1/2" diameter tool, we would offset it by 1/4".

G41 and G42 are the two codes tha we need to include in the program in order for the machine to calculate the cutter compensation.

G41 is typically used when the cutter is on the left side of the material and it's commonly used in climb milling applications.

G42 is typically used when the cutter is on the right side of the material and it's common to use it for turning applications.

Cutter compensation can be applied in 3 different ways, depending on the machine controls.

The first way is by communicating to the machine the radius of the tool using the P command followed by the radius of the tool like in the following example:

G42 P5.0;

The second way, less common, uses an X value after the cutter comp Gcode:

G42 X5.0;

And finally, the most common way is to just state G41 or G42 to let the machine know we wish to apply cutter compensation and let the machine take the geometry from the tool table and apply it.

To learn more about the subject or expand your Gcode knowledge visit Gcodetutor.com (https://rb.gy/7yzqfn).

Stay tuned for more machining videos!

~~~~~~~~~~~~~~~~~~~~~~~~~~~~

Recommended CNC programming books:

Fanuc CNC Custom Macros https://amzn.to/370yX0P

CNC Programming Handbook https://amzn.to/2MPxT9g

CNC Programming Techniques https://amzn.to/3aTS4el

~~~~~~~~~~~~~~~~~~~~~~~~~~~~

Practical Machinist is the largest and most engaged #metalworking community across the web. With more than 160,000 registered members and 300,000+ social media followers, Practical Machinist is the easiest way to learn new techniques, get answers quickly, and discuss common challenges with your peers. Visit Practical Machinist today to join the community and start connecting with your peers.

Become a Practical Machinist member (https://www.practicalmachinist.com/)

Like us on Facebook ( / practicalmachinist )

Follow us on Instagram ( / practicalmachinist )

Follow us on Twitter ( / prac_machinist )

Connect with us on LinkedIn ( / practicalmachinist )

#Cuttercompensation #Gcode #CNCmachining