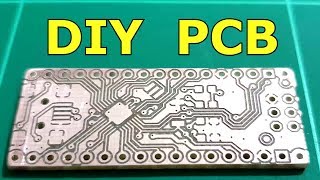

DIY PCB on a 3018 PRO CNC using Single Sided Copper Clad FR-4

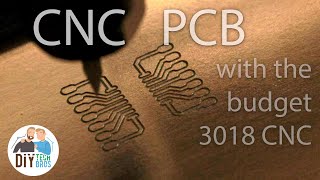

This is a video of my DIY milling of a single sided PCB (FR4 copper clad) using a CNC3018 PRO and laser etching the front fiberglass i.e. FR4 face using a 7W blue laser to mark components and values.

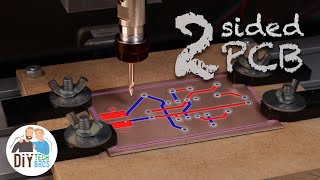

The back copper plane and front fiberglass face were processed using slightly different toolchains.

Copper Toolchain

1. KiCad EDA: https://www.kicad.org'>https://www.kicad.org

2. FlatCAM: http://flatcam.org

3. Candle: https://github.com/Denvi/Candle

Fiberglass Face

1. KiCad EDA: https://www.kicad.org'>https://www.kicad.org

2. Inkscape: https://inkscape.org

3. LaserGRBL: https://lasergrbl.com

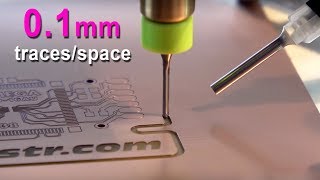

Note: The video was made over multiple milling attempts using different sized vbits. The final PCB shown was made using a 30° 0.1mm Vbit whereas the milling footage is using a 30° 0.2mm Vbit.

Chapter Timestamps

00:00 Create Heightmap

00:45 Milling Process

01:27 PTH Drilling

02:01 NPTH Drilling

02:46 Board Cutout

03:19 Preassembly Inspection

04:17 Postassembly Inspection