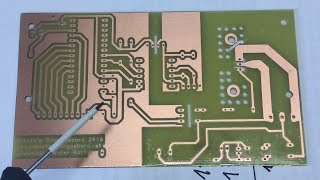

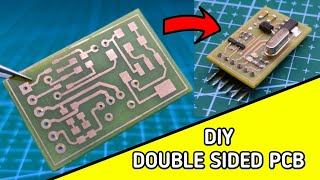

EP7 – DIY PCB – Best DIY PCB EVER! (Double Sided SMD)

So this is where the magic will hopefully happen, I finally make a high density double sided PCB. Will I succeed? Will I fail? Watch the video to find out!

This is the seventh episode in a series where I am challenging myself to make the best possible DIY PCB’s using commonly available low cost CNC technologies.

Below is some detailed documentation about my method.

[SOFTWARE USED]

KiKad Version 6.0.6 (Circuit & PCB Design)

FlatCAM Version 8.994 BETA (Generates GCode, but requires editing)

Grblcontrol (Candle) Version 1.17 (CNC Control)

[CNC SETUP]

RATTMMOTOR CNC 3018 Pro (with modifications as follows)

Aluminum 3018 ZAxis Module + XAxis upgrade kit

StepperOnline NEM17 42Ncm Stepper Motors (x3)

LaserTree Gold 450nm 40WPro 12V 20mm Fixed Focus Laser

Custom end stop switches (x6)

Custom emergency stop button

Custom Z & XY probe

Custom cable management

Custom waste board & PCB Mount + Locating Pins

0.7mm & 3mm End mills (Range of sizes on hand is recommended)

Using ThinkPad E495 to control the CNC

[OTHER EQUIPMENT]

Elegoo Mercury UV Exposer

MiniBandsaw

150 Mesh Silkscreen

150mm Embroidery Ring

10cm Rubber Spatula

Fine haired toothbrush

Ikea glass & plastic containers

Hand File

[CONSUMABLE ITEMS]

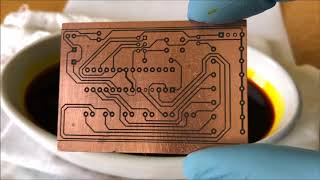

Ferric chloride etchant solution

70mm x 100mm Double Sided Copper Clad FR4 PCB

Ferric chloride etchant solution

Mechanic UVH900WY 10ml UV Resin (White) Fast 10sec curing

WNB UVW100 100g UV Resin (Green)

Conduction CDLT528 138 degree leadfree solder paste

Hozan H423717 0.8mm flux core leaded solder

0.7mm wire (for vias)

Isopropyl Alcohol (99.8% or greater)

Tissue Paper

*********** KiCad Track & Clearance Information ***********

Grid = 0.3175

Clearance is factor of 0.5 with minimum of 0.15 (0.1mm laser 50% overlap)

Track width minus clearance should be factor of Grid (examples follow)

0.3175 0.15 = 0.1675

0.6350 0.20 = 0.4350

0.6350 0.25 = 0.3850

0.6350 0.30 = 0.3350

Fill clearance 0.2mm and min width 0.25. Must be 0.635 from board edge

Board cutout line 0.1mm thick with 0.635 radius corners

Push 45 degree tracks so they are snug to each other

Standalone pads should have a 0.4mm stubby track to sink heat during clearing

*********** FLATCAM FILE PREP ***********

[Double Sided Tool]

Set Axis Y 2places

Mirror operation set W/2,0

Mirror back layers

Drill hole 3.6mm

Set grid 0.5

Locate 2 holes 2.5,2.5 from left corners (shiftclick to copy valuethen +Add)

Create excellon object

** Mill & laser origin alignment still an issue. I am working on this...

[Copper]

Isolation Routing

0.1mm tool, 18 passes, 50% overlap

Generate geometry

Ztravel 0, XY feed 500, Zfeed 1000, spindle 4000 (So far this looks good. Possible cooler is even ok, but risky)

Generate CNC job

Save CNC Job

Use Text editor to replace unwanted Zmoves & other

[Silkscreen]

Isolation routing

0.001mm tool, 1 passes, 0% overlap

Generate geometry

Paint Tool

0.1mm tool, Overlap 50%, Offset 0, Method Standard, Disable connect

Generate geometry

Ztravel 0, XY feed 500, Zfeed 1000, spindle 2500 (So far this looks good. Possible cooler is even ok)

Generate CNC job

Save CNC Job

Use Text editor to replace unwanted Zmoves & other

Save modified version with spindle 150 (For setting UV resin) add "_UV_Expose" to filename

(150 works well with fast resin "Mechanic" white, clean with alchohol & final UV expose for 30 secs)

[Mask/Clear Pads]

NOTE: This setting is usable but must be improved.

Isolation routing

0.001mm tool, 1 passes, 0% overlap

Generate geometry

Paint Tool

0.1mm tool, Overlap 0%, Offset 0, Method (Lines), Disable connect

Generate geometry

Ztravel 0, XY feed 800, Zfeed 1000, spindle 2500 (Leaves some residue for cold pads, but any hotter is no good)

Generate CNC job

Save CNC Job

Use Text editor to replace unwanted Zmoves & other

[Board Cutout] (Board Cutout line is 0.1mm, round corners)

Cutout Tool

Tool 0.1, CutZ 0.858, MultiDepth 0.058, Margin 0, Gaps (None)

Generate Geometry (X)

Select geometry

Ztravel 2, XY feed 500, Zfeed 1000, spindle 10000

Generate CNC job

Save CNC Job

Make sure cut line well with etched copper zone!

[Alignment Drills]

Drilling Tool

CutZ 7, TravelZ 7, FeedZ 50, Spindle 10000

EndMoveZ 25, PreProcessor (GRBL_11_no_M6)

Generate CNC Job Object

Save CNC Job

[Pad Holes]

Drilling Tool

CutZ 2.5, TravelZ 1.5, Spindle 10000, Dwell 1

ToolChange 25, EndMove Z 25, PreProcessor (GRBL_11_no_M6)

Generate CNC Job Object

Save CNC Job

![Toner transfer without heat PCB [ easy way ]](https://i.ytimg.com/vi/p3aRRSdQjxY/mqdefault.jpg)