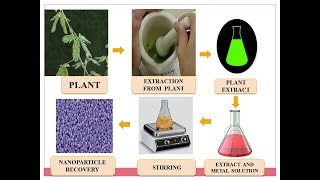

Green Synthesis of Zinc Oxide Nanoparticles / From Plant Collection to ZnO Synthesis and Analysis

This video clearly explains green synthesis of ZnO nanoparticles using plant extract Vitex negundo. The experimental parts clearly include plant collection, extraction, synthesis of Zinc oxide nanoparticles and all required analysis. This one video more than enough to understand the required details for green synthesis of any nanoparticles.

Some key notes on green synthesis of nanoparticles:

1. If you are using leaves as plant material for green synthesis, please collect the fresh leaves of plant. Better you collect the plant leaves same day when you are doing experiment. This is because fresh leaves contain rich in polyphenols and other phytochemicals. This phytochemicals only will act as reductant for metal salts. The dried plant leaves not preferred for green synthesis. Some exceptional case you can use dried plant leaves also

2. After collecting plant leaves please kindly wash the leaves by RO water, distilled water and finally double distilled water

3. Please kindly use double distilled water for extraction to get good yield of nanoparticles

4. While preparing leaves extract, temperature should be 6070 degree C. Should not exceed more than70oC since some of the phytochemicals are thermolabile (Decomposes), then green synthesis process will affect

5. After extraction process completed, the extract should be stored in 8 to 10 degree C. While doing experiment you can take the extract from storage

6. Don’t avoid water and ethanol washing steps, otherwise you won’t get pure zinc oxide nanoparticles. You will get zinc oxide with unreacted zinc nitrate and phytochemicals

7. Use silica crucible for drying process, avoid using of any glassware for drying

8. In this work we used 5 volume of water (50 g leaves in 250 mL of water). Some times you can use 10 volume of water (for 50 g leaves in 500 mL of water)

9. This method applicable for all other plant material also

Some Alternatives in experimental procedure:

1. We used Magnetic Stirrer for making of solution. If magnetic stirrer not available means you do simple glass rod stirring.

2. We used oil bath for heating purpose. You can also use water bath or hot plate or heating mantle or magnetic stirrer hot plates. But make sure that temperature is correct what we are expecting.

3. For filtration of plant extract, we used vacuum pump. If vacuum pump not available means, you can use normal glass funnel for filtration with whatman filter paper 1. But it will take more time when compared with vacuum filtration.