How it's Made - Top 7 Metal Manufacturing Methods

Hi guys we see a lot of different metals in out everyday life. Have you ever wondered how did those shapes are made? Metals are everywhere – in our cars, buildings, even the smartphones we hold! But how do these raw materials transform from deep within the earth to the incredible objects we use every day? Let's find out!

In this video we will learn about the basic manufacturing practices and an overview of how metal is extracted.

Lets start with The Birth of Metal.

Metals are extracted from the earth in two main ways: surface mining, where large machines scoop up ore from open pits, and underground mining, where tunnels are dug deep beneath the surface.

The extracted ore is a mixture of desired metal and unwanted rock. It's then crushed and sent to a processing plant. All these crushed rocks are then filtered in these giant furnaces and unwanted elements are separated from metal. All the dust and impurities are filtered using different chemicals and intense heat. At this stage we get our metal in Molten form. After that we process those metal into secondary processes.

So that is how metal is separated from the earth.

Lets understand the manufacturing processes.

In the whole worlds there are some basic principles of shaping things on which all the manufacturing methods are based.

1. Material removal processes : The basic concept of this method is to remove material to get the desired shape. A simplest example of this is when you use sharpener to sharp the pencil. It is one type of a material removal process to get the desired shape. When you use certain tools you can even cut down metals to get them into the shapes that we need. These processes are further catogerised as

1 Machining where you see some examples like drilling , cutting , boaring , milling etc.

2Abrasive Machining where you see grinding , polishing buffing etc.

3. thermal processes like laser cutting , plazma cutting oxy fuel cutting etc/

3. Material adding processes: this process is also very widely used in industry. to explain in the simpelest way when you want to join 2 papers how you use a glue as an agent to join 2 similler material.

To give you some engineering exmapls you can see methods likes Welding , Soldering,brazing , 3D printing and gluing .

4. Material shaping by melting metal which is known as casting. in this method we melt the metal and give them the shape of the die and when they solidify. to explain this in a simple way how you have a ice cube in different shape depending on the ice forming plate from water. same principle is in the play here.

5. Now lets go to next manufacturing method where metal is heated in a semi solid form and then deformed using more power or force. this method is known as forging. you might have seen some of these method in the movies where sward smith heat up the sward and uses hammer to shape it.

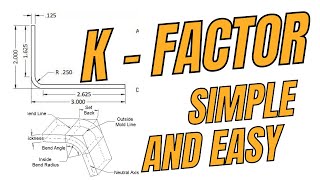

6. Number 6 . forming forming is nothing but a method to apply enought pressure on the metal or sheet of a metal that material enters plasting deformation and changes theie shape. some of theire example is in the car and motor bodies or metal boxes where it is formed to deformed into a shape which can be useful.

7 Last method is joining . Joining is a method where we combine any of the above methods a to get the desired shape that we need to acheive. best example of this is how different parts of the car are joined together with welding and also using nut and bolt which are made using machining method.