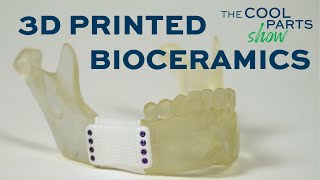

Improving Medical Implants with 3D Printed PEEK | The Cool Parts Show #63

Polyether ether ketone (PEEK) is used in medical implants for its modulus akin to human bone as well as its radiolucence, giving physicians a clear view of a healing injury via Xray. Implants made from this material until now have mostly been molded or machined, in part because of the challenges of 3D printing PEEK. The large delta between the material’s glass transition and melting temperatures makes the polymer tricky to apply with standard fused filament fabrication (FFF). Curiteva instead uses a novel 3D printing method called fused strand deposition (FSD), which does not fully melt the filament and actually pulls the material along as it is being deposited. The company has achieved FDA approval and is now in production for its first 3D printed PEEK implant, the cervical spine cage featured in this episode.

This episode of The Cool Parts Show is brought to you by Carpenter Additive: https://www.carpenteradditive.com/

LEARN MORE ABOUT:

Curiteva, maker of this implant https://curiteva.com/

Vestakeep, the Evonik material from which Curiteva’s PEEK filament is derived (Evonik also assisted in the FDA approval process for this device) https://www.additivemanufacturing.med...

Another episode on a medical implant made from polymer (in this case, PEKK applied with selective laser sintering) www.additivemanufacturing.media/kc/coolparts/articles/moreaffordablesutureanchors3dprintedfrompekkthecoolpartsshow60

How to think about 3D printing with highperformance polymers like PEEK https://www.additivemanufacturing.med...

Subscribe to THE BUILDUP, Additive Manufacturing Media's newsletter on 3D printing for industrial production: https://gbm.media/JoinTheBuildUp