Information on the 4 Cylinder Gasoline Engine M 271 EVO | Mercedes-Benz

Brief description:

M 271 EVO

From September 2009 the M 271 EVO will be used in

the BlueEFFICIENCY models of the CClass and

EClass. There are three power variants: 115, 135 and

150 kW.

The development of the M 271 EVO combines the

following objectives:

• Improved responsiveness due to increased power

and higher torque

• Improved comfort thanks to smoother running

• Significantly lower fuel consumption and reduced

CO2 emissions

• Compliance with the Euro 5 standard

The M 271 EVO therefore combines the

BlueEFFICIENCY requirements for economy and

environmental compatibility with comfort and driving

pleasure.

These objectives are realized by a variety of technical

innovations and improvements:

• Lownoise and lowmaintenance chain drive

• Camshaft adjustment

• Lanchester balancer

• Homogeneous direct injection with 140 bar

injection pressure

• Fuel injectors

• Quantitycontrolled fuel pump

• Turbocharger

• Lambda control

• Secondary air injection for rapid heating of the

catalytic converter

• Twodisk thermostat with threedisk functionality

• Radiator shutters

• Regulated oil pump with high efficiency

• Ignition system

• ECO start/ stop system

Overview of new features and improvements

1 Exhaust system with turbocharger, optimized lambda control and secondary air injection

2 Ignition system

3 Homogeneous direct injection with quantitycontrolled fuel pump

4 Fuel injectors

5 ECO start / stop system

6 Regulated oil pump

7 Lanchester balancer

8 Radiator shutters

9 Twodisk thermostat with threedisk functionality

10 Lownoise and lowmaintenance chain drive with optimized camshaft adjustment

Cylinder head:

The cylinder head and the intake valves have been

adapted to cope with the demands of homogeneous

direct injection.

The M 271 EVO operates according to the fourvalve

concept with two camshafts, two camshaft adjusters

and central spark plugs.

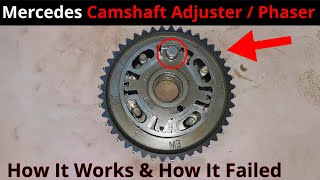

Camshaft adjuster

The camshaft adjusters of the forged intake and

exhaust camshafts are vanecell adjusters and have

been further improved. They allow the timing to be

varied steplessly and more quickly than before.

The camshaft adjuster is a hydraulic swivel drive. The

adjustment angle is 40° (crank angle) – corresponding

to an angle of 20° performed at the adjuster

(exhaust). The adjustment of the camshafts optimizes

the engine torque curve and improves exhaust charac

teristics.

A springloaded pin locks the camshaft adjuster in the

basic position when the engine is switched off in order

to prevent uncontrolled movement of the adjuster

during startup.

The new camshaft adjuster is 34% lighter while the

rate of adjustment is twice as fast.

Crankcase

Crankcase ventilation

The M 271 EVO features two crankcase ventilation

systems:

• Partial load ventilation with single cyclone oil

separator

• Full load ventilation with double cyclone oil

separator

Partial load ventilation

The single cyclone oil separator is responsible for

separating the oil at the partial load ventilation line.

The partial load ventilation line runs from the left

engine support flange into the charge air distribution

line downstream of the throttle valve actuator.

Via an opening in the crankcase the blowby gas (blow

by quantity) flows into the single cyclone separator

which is located behind the left engine support. The oil

separator is in the form of a cyclone: Incoming air is

made to spiral and the resulting centrifugal forces

separate the oil, which flows back into the housing.

The air cleaned in this way leaves the oil separator

through a combination valve installed above the

cyclone, which acts as a check valve in the event of

overpressure in the charge air distribution line and as

an air shutoff valve to protect the catalytic converter.