Seawater Electro-chlorination | Working Principle

The onsite generation of Sodium Hypochlorite solution from seawater is performed by the electrochemical process providing partial electrolysis of Sodium Chloride contained in seawater, as it

flows through direct current energized anodic and cathodic electrodes.

Filtered seawater feeds the NaOCl generator module.

The Electrochlorination Unit is composed of electrolyzer module, power cabinet and Control cabinet.

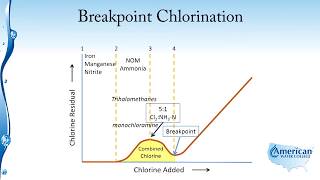

The Sodium Hypochlorite solution is stored and degassed in a storage/degassing Tank and is injected into the seawater pipes and heat exchangers to prevent blockage in the system.

Usually continuous dosing is 22 hours a day.

Shock Dosing: 30 minutes every 6 hours @ 3 times normal dosage rate four times a day.

The Hydrogen gas disengages from the liquid phase in the upper part of the storage tank, it is flushed with air in order to keep Hydrogen concentration less than 1% by volume and it is vented to open air.