Sheet Metal Basics: What is the K Factor? Calculator link in description

https://www.themetalcut.com/kfactor...

Excell sheet for K Factor Calculator Just 1 $ : https://dmetalart.company.site/produc...

Finding correct K factor is very important. Many people have confusion about what is the importance of K factor , why we need K factor.

How to find correct K factor.

K factor directly impacts the length and shape of sheet metal part. It does not make much difference in simple parts with 1 fold but when it comes to thick and multiple folds it makes a huge difference in getting the correct length.

In this video I have explained why it is important and how to find K factor of your sheet metal.

what is k factor , why K factor is important and how to find Kfactor.

To find the K factor you can go to following link where you can input all the data and get the correct K factor.

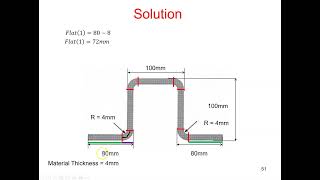

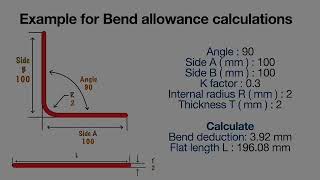

The K factor is an important parameter used in sheet metal fabrication to calculate the flat pattern length of a sheet metal part. The K factor represents the ratio of the neutral axis to the material thickness and is used to calculate the bend allowance.

To find the K factor in sheet metal, you can use the following steps:

Determine the material type and thickness of the sheet metal being used.

Determine the inside bend radius of the bend you want to make.

Use a Kfactor chart or formula to find the K factor value for the material type and thickness, and the inside bend radius. The Kfactor value is often provided by the manufacturer of the sheet metal or can be found in reference tables.

Apply the Kfactor value in the bend allowance formula to calculate the flat pattern length of the sheet metal part.

Here is the formula for calculating the bend allowance with the Kfactor:

Bend Allowance = (π/180) x Bend Angle x (Inside Bend Radius + KFactor x Material Thickness)

Note that the value of Kfactor may vary depending on the type of sheet metal, the tooling being used, and the process of bending. Therefore, it is always a good practice to consult the manufacturer's specifications or reference tables to ensure accurate calculations.

#engineering #mechanicalengineering #sheetmetal #solidworks #pressbreak #metalforming

#science