Steel: How It’s Made Poured and Formed (Steel Making Process Explained)

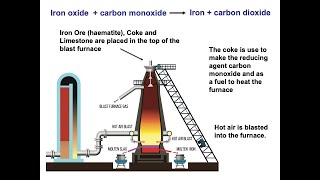

in my last video I explained how Iron ore is converted into the Pig iron using a blast furnace. In this video we will understand what happens after that.

So as you know pig iron is a very impure form of iron. Even after the process of blast furnace it still has some impurities like Sulphur , silicon and phosphorus .

To understand the next process lets see where we use the steel. So we use in different places for different uses. for example we use steel to make kitchen utensils and we also use steel to make a car. But the question is Do we use same steel for both application ? Answer is No. We use the steel that we need for the application. There are many different kind of steel available in the market.

To explain this simply imagine you are going to a cafe. there you will can get Mocha, cappichenio , Flat white and English breakfast tea etc .They all taste different but the basic element is the same that is Milk and you adjust the properties of milk with different mixtures to get what you like. Similarly the basic element in the steel is Iron and you adjust it's properties by mixing different elements to get the desired properties.

You can think of steel making like a recipe to make up the final product. In steel these ingredients are called alloying addition. every ingredient effects the proporties like strength, hardness, ductility ect. in different way.

So main elements that can effect the properties are carbon, silicon, manganese , phosphorous, Sulphur , chromium, molybdenum, nickel. One of the most important element for this is Carbon. for example pig iron is a hard but brittle element. Certain amount of carbon increases tensile strenght and hardness. on the other side sulpher reduces ductility and thoughness and weldibility. But same sulpher is added to manufacture machined parts as they reduces thoughness. Another example is Chromium is added to the steel to increases corrosion resistance. Normally you will find that chromium is the main element in Stainless steel after Iron.

Now you have idea of what different elements do lets understand how its done.

All the magic happens In the furnace called LADLE furnace (LMF). Ladle furnace is nothing but a furnace where steel is heated around 1700 deg celcious using electrodes to refine the steel.

When steel is heating up it releases Argon gases which gives bubbles on the moltan steel. Just like how we use straw to bubble the water. At the same time Other Alloys are added as per the requirement to make the desired steel.

Now all theses process is controlled by computer to get accurate quantity of alloying elements. because of all that bubbles still the remaining impurities comes on the top and the mixture is properly mixed up with alloys. This furnace has a small hole opening from where sample is taken to check the chemical composition to make sure that we are getting the quality of the steel that we need.

#howitsmade

After we get the desired quality of steel we further transfer ledel to a foundy shop where this steel is further shaped in to desired shape. forexample in the world most of the steel is used in sheet metal requirement then they will be in the raw shape of ractangle. but if you are making rail tracks or SHS or RHS it will be cooled in those shape. Once we get the shape it's still not over it needs to cool down with specific method where it can follow iron formation.

IF you are using them in sheet metal they are further rolled when hot in desired rollers and rolled in coil shape.

Let me know if you like this video and comment me if you want any specific video in steel making .

#sheetmetal #metalforming #sheetmetalfabrication #metal #science #engineering #iron #steelmaking #steel #furnace #metalmanufacturing

Sources

• Video

• Steel Types Stainless Steel Vs Carb...

https://byjus.com/questionanswer/wha...

• What is Stainless Steel?

• Steel Metallurgy Principles of Meta...

• ladle furnace (secondary metallurgy) ...

• How STEEL is Made From Dirt to Molt...