SZL seies coal fired chain grate boiler - 3D animation version

Contact me at whatsapp +86 18861589035

or email [email protected] get the quote

→→→→→→→→→→→→→→→→→→→→→→

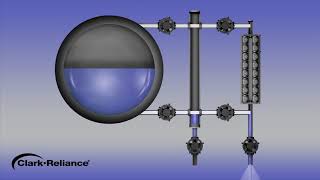

ZOZEN is a wellknown international industrial boiler manufacturer and SZL series of coalfired boiler is one of its patented products. SZL series of boilers, with thermal capacity from 4t/h to 35t/h, adopts a horizontal doubledrum structure and a chain grate furnace. It has the characteristics of wide coal adaptability, less occupied area, convenient installation and high thermal efficiency.

The main parts of the boiler include the drums, watercooled wall, furnace, chain grate, furnace wall, etc.

The boiler system customized by ZOZEN can effectively increase the thermal efficiency.

The running processes of fuel supply, ash discharge and slag discharge are highly automatical, which can reduce the cost of operation and maintenance for users.

The largevolume furnace reduces the thermal load and coking in the furnace.

The fine ash produced by coal combustion is discharged from furnace by a welldesigned ash removal device, which ensures the safe operation of the boiler.

The air required for coal combustion is sent into independent wind chambers by the forced draft fan, and then enters into the furnace through the grates to react with coal for combustion. The hightemperature flue gas from combustion enters into the Stype convection section, then into the economizer to reduce the flue gas temperature to the economical exhaust temperature, and finally enters into the cyclone. The energy saving and environmental protection effects are significant.

The soft water, generated from water treatment, enters into the soft water tank, and is sent to the deaerator by the deaerator water pumps. And the deaerated water is sent to the economizer through the feedwater pumps and absorbs flue gas heat there, then enters the steam drum. The steamwater mixture generated by the heat exchange of the furnace watercooled wall and the convective heating surface enters the steam drum. After the steamwater mixture passes through the steamwater separator in the steam drum, the highquality steam is sent to the steam distributor through the main steam pipeline, and then distributed to workshops by the steam distributor. On the premise of ensuring safety and reducing costs, the control system has the functions such as automatic water supply, overpressure protection, extremely low water level protection, etc., as well as realizing remote centralized control.

ZOZEN is bringing the warm to the world.

#coal #watertube #chaingrate #boiler #boileroperation