The BIG Build Begins - Scale L-1011 RC Airliner Center Fuselage - Part 1

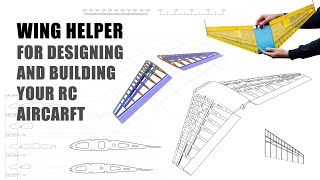

I designed a scale model airplane, from a blank canvas in Fusion 360 to a model that can be manufactured. Now I start to build the design I 3D modeled in CAD using a brand new 100 watt laser cutting machine, 3D printer and a lot of trial and error. I've been an aviation lover for as long as I can remember. Being able to build an airplane from scratch, even as scale plane, is very exciting and I wanted to share the whole process from CAD Design to building and ultimately the maiden flight.

In this very 1st episode in this series of RC airplane build videos, I assemble the center fuselage frame of the 1/20th scale Lockheed L1011500. It's the keystone of the entire airplane.

Featured in this episode are 3D printed wing mounts using MatterHackers NylonX on the Raise3D Pro 2. A few peeks at the Vank Laser cutting machine which was used to cut over 100 parts of 3mm birch plywood, which makes up the fuselage frame.

See the Assembly Guide and follow along: https://www.rccad2vr.com/l1011build...

⭐ KIT PREORDER : https://www.rccad2vr.com/trijetkitp...

⭐ @Raise3D Pro 2 : https://www.raise3d.com/pro2/

⭐ NylonX by @MatterHackers

⭐ Sample 3D Materials from @VisionMiner : https://www.visionminer.com

⭐ Music from @epidemicsound : https://www.epidemicsound.com/referra...

0:00 Welcome

1:01 Laser Cutting Airplane Frame

2:29 Wingbox Assembly Start

6:56 Wingbox Spacers

13:10 NylonX 3D Printed Airplane Wing Mount (Carbon Fiber Nylon)

14:22 Wing Mount Guides and Rails

16:26 Section 1 Review

19:13 Landing Gear Bay

23:35 Electronics Hatch, Longerons, and Strings

https://www.rccad2vr.com

Follow on:

IG: / rc.cad2vr

TikTok: https://vm.tiktok.com/ZMdqVYGtT/

Twitter: / cad2vr

Pinterest: / seafuzz

Behind the Scenes:

The Vank Laser Cutting machine was purchased online direct from the manufacturer and shipped via container ship from Shanghai to Seattle. It was a nerveracking 3 month experience.

This was my second attempt at building the center fuse, the first iteration failed due to a faulty keel design.

This video was shot over the course of 4 days and editing took 4 around the clock days.

I have over 60 hours of footage that was whittled down into this 30 minute video.

The wing mount's failed to print 4 times at about the 10 hour mark. The parts would warp off the build plate. MatterHackers suggested Garolite as the build surface best for NylonX. The new build plate worked the first time.

![How To Start Designing RC Airplanes in Fusion 360 Tutorial [Episode 1]](https://i.ytimg.com/vi/_7vmUEARiYE/mqdefault.jpg)