Ultrasonic melt processing of metals: fundamentals u0026 applications

A talk by Dmitry Eskin of Brunel University, given to the Warwick Manufacturing Group, organised by Prakash Srirangam.

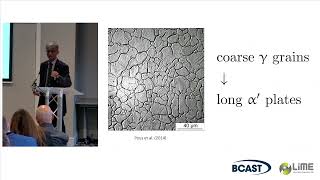

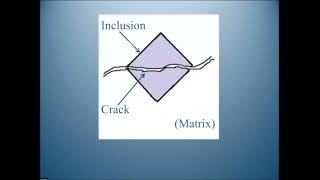

Ultrasonic processing has been applied to treating liquid metals for decades, yet the fundamental mechanisms involved became clearer only in the last 20 years due to the new methods and knowledge available. In this talk, the main mechanisms of degassing, nucleation, fragmentation, deagglomeration and atomisation will be covered as well as the major applications to processing aluminium alloys, e.g. melt degassing, structure refinement upon DC casting, manufacturing composite materials and rapid solidification for additive manufacturing.

Dmitry G. Eskin received his Engineering and PhD degrees from Moscow Institute of Steel and Alloys (Technical University, Russia) in 1985 and 1988, respectively. After that he worked as a Senior Scientist in the Baikov Institute of Metallurgy (Russian Academy of Sciences) (19881999); a Senior Scientist and a Fellow in the Materials innovation institute (The Netherlands) (19992011); and an Associate Professor in Delft University of Technology (The Netherlands) (20082011), where he conducted fundamental and applied research on solidification processing of metallic materials and alloy development, with major contributions to mechanisms of hot tearing, macrosegregation and grain refinement upon directchill casting. In 2011 he joined Brunel University London (U.K.) as a Professor in Solidification Research. His current research concerns fundamentals and application of ultrasonic cavitation to melt processing as well as alloy development. He is a wellknown specialist in physical metallurgy and solidification processing of light alloys, author and coauthor of more than 350 scientific papers, 7 monographs, and a number of patents. Among his books are “Multicomponent Phase Diagrams: Applications for Commercial Aluminum Alloys” (2005), “Physical Metallurgy of DirectChill Casting of Aluminum Alloys” (2008), “Ultrasonic Treatment of Light Alloy Melts” (2015). Prof. Eskin is a former Chair of TMS Aluminum Committee, former editor of Journal of Alloys and Compounds, current member of the editorial boards of Ultrasonics Sonochemistry, Metallurgical and Materials Transactions A and JOM. He also is a recipient of two TMS Cast Shop for Aluminum Production Awards (2011, 2013) and TMS Light Metals Technology Award (2013).

![The moment we stopped understanding AI [AlexNet]](https://i.ytimg.com/vi/UZDiGooFs54/mqdefault.jpg)